Location

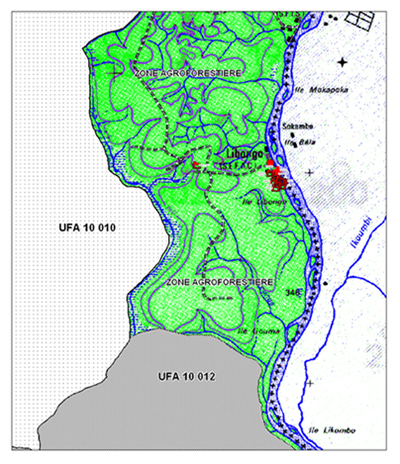

The Libongo sawmill was created in 1968 at its present site on the Cameroon side of the River Sangha, at the south-eastern border of Cameroon with the Central African Republic. It is located about 100 kilometres from Salapoumbé, Salapoumbé Arrondissement, Boumba and Ngoko Département, East Province of Cameroon. The map in Figure 1 below shows the location of Libongo.

More specifically, it is situated in the agroforestry strip along the River Sangha, on its left bank on the Cameroon side, to the east of UFA 10-010.

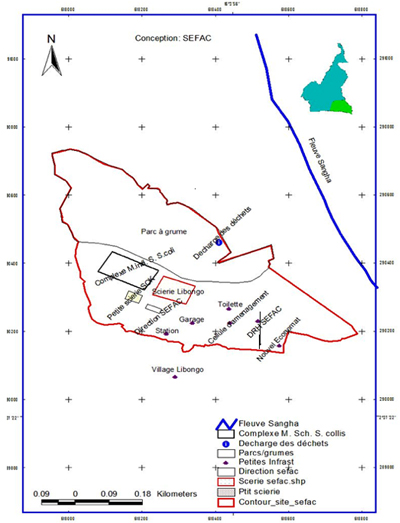

SEFAC owns plot nos. 1090, 1091, 1092, 1093, 1094, 1095 and 1096 on its Libongo site; they are registered in the Boumba and Ngoko Département Property Register and cover a total of about 35 hectares, occupied by its various infrastructures.

Figure 1 – Location of the Libongo sawmill

Factory data

- 3 sawing lines with a capacity of 40,000 m³;

- An industrial joinery shop with a manufacturing volume of approx. 30,000 m³;

- Main tree species: Ayous, Sapelli, Assamela, Padouk, Tali, Bosse, Iroko, Sipo, Kossipo, Bete, Frake, Bibolo, Acajou, Paorosa, Muculungu and Tiama;

- Personnel: 360 employees;

- 8 drying cells with a capacity of 1,200 m³.

About the operator (SEFAC)

Société d’Exploitation Forestière et Agricole du Cameroun (SEFAC) has been registered in the Trade and Personal Property Credit Registry since 1967 under no. RC/DLA/ 1967/B/03266. The company, based in Douala, was incorporated under Cameroon law in 1968, and its activities have contributed a great deal to the development of Libongo village. It is an authorised logger registered under no. 189, Order No. 015 of 8/01/80, and became a société anonyme (public limited company) in 1990.

SEFAC owns the Libongo factory, which performs primary processing of wood into timber, secondary and even tertiary processing, at a sawmill and an industrial joinery unit.

SEFAC processes and markets the wood it harvests in the logging concessions allocated to it in the Boumba and Ngoko Département, namely UFA 10-008, 10-010 and 10-012.

Presentation of SEFAC, the initiator of the environmental audit:

- Company name: Société d’Exploitation Forestière et Agricole du Cameroun;

- Legal status: Société Anonyme (public limited company) under Cameroon law;

- The company’s objects: Industrial processing and marketing/export of timber;

- Taxpayer no.: M116700000360 F

SEFAC’s organisation

SEFAC’s organisation chart comprises:

- a Board of Directors [shared] with 2 other companies, namely Société d’Exploitation de Bois d’Afrique Centrale (SEBAC) and Filière Bois (FB)

- a General Management shared with the 2 companies, part of which is based in Douala, and part in Libongo

- a Sales Manager

- nine (09) Units with various parallel responsibilities (Health, Administration and Personnel, Vehicle Garage, Heavy Machinery Garage, Logistics and Security, Forestry Management, Traffic, Sawmills, and Industrial Joinery)

- some of the above units have sub-units or branches.

Figure 2 – Meeting room, planning offices

Geographical location of site

Libongo is situated at the eastern edge of the South Cameroon plateau. The landform consists of a huge eastward-sloping terrace, which ends abruptly at the River Sangha; it extends featurelessly for nearly 5 km on the west side, followed by a series of valleys and hills with relatively low altitudes (ranging between 350 and 650 metres). This terrace extends northwards towards Béla and southwards to the River Lobéké.

The Libongo sawmill was intentionally built on lateritic terrain which keeps it above water at all seasons, including the waters of the nearby River Sangha, about 200 metres away

Facilities

This industrial unit comprises the administration offices, the sawmill, the production unit, the drying unit, the mechanical workshop, the filing workshop, the heavy machinery garage, the fuel station, the power station, and the oil and grease storage area.

In order to perform its various activities effectively, SEFAC in Libongo has a workforce of 377, comprising 351 permanent employees and 26 day labourers.

The Libongo sawmill consists of a complex of buildings and facilities, the main ones being:

- the administrative buildings, which house the Libongo General Management, the factory management and its functional structures (secretarial office, personnel office, administration and accounting); the other departments (foremen, garage, management unit, etc.);

- buildings and sheds associated with sawing and timber production activities, namely:

- the offices of the production managers (manufacturing department, maintenance and repair department, logistics department, etc.)

- primary processing wood sawing lines

- secondary and tertiary processing joinery shop

- sawing line maintenance workshops

- storage depots for spare parts and products for wood

- packaging workshop, saw-filing workshop, workshop making mechanical parts for the sawing lines and joinery, and plumbing workshop

- sheds containing thermal power station, boilers and dryers

- service station (diesel, petrol and lubricants) with tanks and fuel pumps having a storage capacity of 274,000 litres

- heavy machinery garage

- small drinking-water treatment unit with storage tank

- facilities and areas designed for removing sawdust and solid waste and/or sorting recovered wood

- log storage area and timber storage areas

- amenities (infirmary, company store, dispensary, changing rooms, etc.)

- gatehouse controlling access to the sawmill facilities.

The various elements described above are shown in the sawmill layout plan in the figure below (Figure 3).

Figure 3 – The plan of mass of the sawmill

Manufacturing organisation

In addition to maintenance tools, the Libongo sawmill has 3 sawing lines, a small recovery factory, an industrial joinery, 2 boilers and drying chambers with a capacity of around 1200 m3, maintenance and filing workshops, and a power station.

Manufacturing tools and equipment

The Libongo sawmill has three processing lines, two of which are operational, while the third is currently being installed. Each line comprises a set of machines that give the wood the required dimensions.

Each complete sawing line comprises the following machines:

- a BONGIOANNI horizontal band saw used for preliminary preparation before the head saw is used

- three BONGIOANNI head saws

- four COSMEC, SOCOLEST, CML or SEFAC Model edger saws

- two BONGIOANNI and BRENTA resaws

- six STROMAB, OMEC or OMGA trimmers

- two ARTIGLIO single-blade saws

- nine INCOMAC, CEAF or HILDEBRAND operational dryers with a capacity ranging between 120 and 130 m3 each

- two INCOMAC and PELUCCHI boilers

- five generators, two 850 KVA, and the other two 1000 kva and 450 kva.

- four small multiblade saws for the small factory serving as a recovery line

- three multiblade saws for the industrial joinery shop.

Figure 4 – Artiglio single blade

Personnel

LThe Group has created seven hundred (700) permanent jobs at its various facilities since 1998, thereby answering the appeal by the public authorities to create jobs. The workforce increased from three hundred and seventy-five (375) employees in July 1994 to a thousand (1000) on 1 May 2001, and then fell to 700 after a restructuring project due to economic difficulties.

Operating in the far south-east of the country, the Group gives priority to local people with a view to their development; they represent 72% of the group’s total workforce, 53% of whom work in Boumba and Ngoko Département and 19% in the other départements of the province, while the other 28% work in the rest of the country.

Raw Materials

The main raw material used in the manufacturing process is wood in the form of logs received from the UFAs allocated to the Sefac Group. Water is also used, together with consumables such as:

- Céremule and paint;

- steel rollers for strapping packages;

- fuels, oils and greases.

Description of manufacturing process

This section describes the process throughout the cycle from the entry of the wood to the factory to its exit from the factory: Incoming log yard – Horizontal band saw – Head saw – Edger saw – Resaw – Trimmer – Sorting and recovery – Packaging – Processing – Drying – Storage of timber packages ready for transport. Connected and associated operations: filing, mechanical repairs, energy production, etc.

Receipt and preparation of logs at the log yard

Incoming logs from the forest arrive at the factory on logging trucks; after the administrative formalities, which involve checking the waybill and recording the entry dates, they are accepted, then sent to the log yard and sorted with the aid of front loaders (Figure 5). The Libongo sawmill has a large log yard on the north side of the factory. The logs are then unloaded from the logging trucks with the aid of front loaders and classified on the basis of wood species and date of entry to the yard on skids made of logs. According to the sawing programme (based on sawmill orders and/or contracts), the logs are removed from the batches, laid on the ground and cut into bolts with a chainsaw. The log yards only have a very slight slope, which sometimes limits water run-off, with the risk of mud formation in the rainy season. However, guttering has been laid in the yard to allow rainwater to run off.

Figure 5 – The log yards

The yard’s personnel comprises:

- yard manager;

- deputy manager;

- two manual workers.

The bolts obtained by bucking logs in the yard are conveyed to the sawing section by front loaders and deposited on the deck, which is equipped with a mechanical system allowing the bolt to be manipulated and introduced into the sawing cycle.

Bolt splitting (horizontal sawing)

This relates to large bolts, and involves splitting them lengthways into two half-bolts or four quarter-bolts (billets), so that their dimensions are compatible with the head saw. Horizontal sawing is performed with a BONGIOANNI horizontal chain ripsaw. In view of the small number of bolts ripped, the horizontal saw only operates occasionally. No environmental concerns have been reported at this workstation

Plank sawing

Performed with the head saw, and involves cutting the bolts or billets conveyed from the horizontal saw into planks of a fixed thickness, as required by the order. The head saw is a BRENTA vertical saw with a flywheel diameter of 160 cm; as the clearance between the knees (the bolt clamping system) is 160 cm, the head saw cannot saw bolts of a size exceeding 160 cm. The operation is conducted by a sawing specialist housed in an automated cabin equipped with a laser system that optimises the sawing stroke. He is helped by an assistant positioned in front of the deck, whose task is to ensure that the bolt to be sawed does not contain nails, to remove hanging bark, stones and steel S’s, and to tighten the saw if necessary. Planks are produced at this workstation. Waste materials mainly comprise bark, sawdust and slabs.

The head saw is fitted with a system that sucks the sawdust through a pipe to the sawdust yard.

Plank edging

This operation is performed with multi-blade edger saws, and involves splitting planks into sections of a width complying with the order. Plank edging also uses the laser to optimise the saw stroke and minimise defects that may be perceived in the planks. It involves sawing the planks parallel to the grain to obtain timber of uniform, regular widths, with edges at an angle of 90° to one another. The waste generated by this workstation is sawdust and edgings.

The sawdust obtained there is recovered with exhausters and conveyed through pipes to the sawdust depot located about 50 metres to the west, where part of it is burned.

The edgings generated by the operation are combined, then conveyed to the waste yards. Some is recovered there by the COLIDESA to supply its edger saw, some is used to fuel the boiler, some is supplied to the local population, subject to authorisation, for firewood and carbonisation, and the rest is incinerated.

Re-sawing

This operation involves using a small vertical saw to recover sawn wood containing minor defects. Parts with defects are completely removed, and the width required by the order is obtained.

The waste generated here is sawdust and cull timber.

End trimming

This operation is performed with electric circular saws or trimmers fixed to bucking tables. End trimming involves cutting off the ends of the edged wood to obtain its final length. The timber thus produced is sent for packaging. In addition to the desired products, the process also generates sawdust and trimmings. Long pieces of cull timber are sorted and packaged for sending to the recovery workshop. The remaining waste is sent to the waste yard.

Sorting

The timber produced by end trimming is sent to a mechanised sorting line along which skilled sorters sort and stack the pieces according to the specifications. Pieces not complying with the orders are removed and stacked separately for sending to the recovery line. Two types of packaging are performed, according to the contract:

- KD packaging (dry order): the packages of wood must stay in the dryer to minimise their water content before being packaged in Polyane and sent to the customer. This relates to white woods (Ayous);

- AD packaging (wet order): the packages of wood are sent direct to customers.

The operations performed here are manual.

UAnother concern is crushing of fingers or feet, injuries, splinters penetrating the fingers, etc.

To deal with these risks, workers are required to wear gloves and steel-capped footwear and to transport heavy items with the aid of a hoist.

Strapping, labelling and treatment

When a package has been put together, it is strapped with a steel strap and identified by labelling with paint. The personnel involved in this stage of the work are provided with appropriate personal protective equipment (PPE).

Drying

90% of white wood such as Ayous is dried in the boilers before storage to prevent deterioration caused by fungi and insects.

The Libongo sawmill has nine drying cells with a total capacity of 1200 m3. The drying time in the dryers varies according to the performance of the dryer and the species of wood used as fuel. The drying heat is supplied by incinerating waste wood (sawdust, slabs, edgings etc.) in a boiler. The heat produced heats water, which is conveyed by a circuit to the walls of the drying rooms where it releases its heat into the room; it then cools and returns to the boiler via another circuit to recover heat and recommence the cycle. Thus the circulation of hot water gradually heats the drying rooms and their contents (in this case, wood). As it is heated, the wood loses water and dries.

The manufacture of heat by the boiler requires a great deal of attention from SEFAC’s managers. If the process is efficiently conducted, it can constitute an alternative to the production of energy by fuel oil-driven engines, because the raw material (in this case, wood) is available in large amounts at a minimal cost compared with that of fuel oil, which would have to be obtained in Douala at an exorbitant price. It is essential for this activity to be mastered and consolidated.

The problems involved in drying are management of the wood ash generated by incineration of waste for energy production, the water that conveys heat to the dryers, and mastery of the operating parameters of the boiler required to ensure optimum efficiency.

When the boiler has shut down and the water circuit has cooled, the ash is removed and disposed of, as is the water used to convey heat when it is replaced.

Timber storage

Pending transport to Douala, the dried timber is packed in polyethylene (plastic) sheets, and stored in a shed on site. The undried timber is placed on pallets in the storage area, in the open air, or packed if necessary. The photo (Figure 6) below shows timber stored on pallets, ready for transport.

Figure 6 – Timber storage in the Libongo area

Associated services

For maintenance of the manufacturing equipment, the sawmill has a mechanical workshop, a filing workshop and an electricity workshop with modern equipment. The mechanical workshop has a mechanical lathe for the manufacture of metal parts, a hoist, a keying machine, a grinding wheel, a drilling machine, a shaper, a moulding machine, a welding station and a blow torch, all in perfect working order.

VASTO LEGNO

VASTO LEGNO